Types of blister packaging

There are 3 main types of blister packaging; the face seal, the trapped blister and the slide on. Each has it’s own advantages and conversely, it’s drawbacks. Both the face seal and the trapped blister require special sealing machinery and tooling. However, you can assemble the Slide-On by hand. All three offer different levels of graphic presentation.

Face Seal Blister Packaging

The most common form of blister packaging is the full face seal blister card. It is comprised of 2 parts. The first part is a .020 thick blister coated card printed with graphics front and back. The front side is treated with an adhesive that also acts as a varnish like coating. The second part is a PVC or PETG “blister” which is vacuum formed over a mold. The plastic blister covers the product and then has a 3/8” “flange” which seals to the blister card.

Both pieces are fitted, along with the product into a blister sealing machine that has been tooled with a sealing tray for that specific package. The blister is loaded, open side up into a cavity in the sealing tray. Next, the product is loaded. Finally, the card is placed face down on top. The card is located and kept in place by spring loaded pins set into the sealing tray.

After the sealing tray is moved into position under the seal head, the heated sealing head is pressed down with tremendous pressure. This pressure pushes the blister and card together. The process melts the adhesive and bonding the 2 parts together.

Trapped Blister

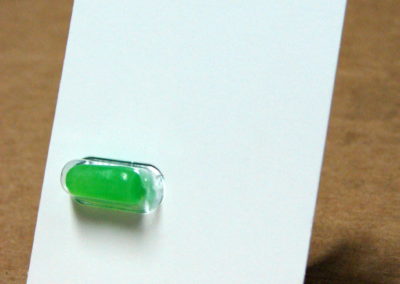

A trapped blister package is a step up from a face seal card both aesthetically and security wise. It is also often used for capsule packaging. Foil backed blisters (which will not seal to a face seal card) can be trapped between the front and back layers. The product protrudes through the front of the package. A trapped card is the same width as a normal card but twice as long and scored in the middle. The front of the card is cut out to leave a hole where the product will sit.

The card is loaded into the tray with the front side down. The blister and product then go into the cutout in the front, and the back is folded over until it sits on the front. This type of card has the adhesive on the inside of the package. When the heat and pressure from the blister sealer are introduced, the adhesive melts and bonds the two halves of paper together. This traps the flange of the blister in between layers.

Slide-On Blister

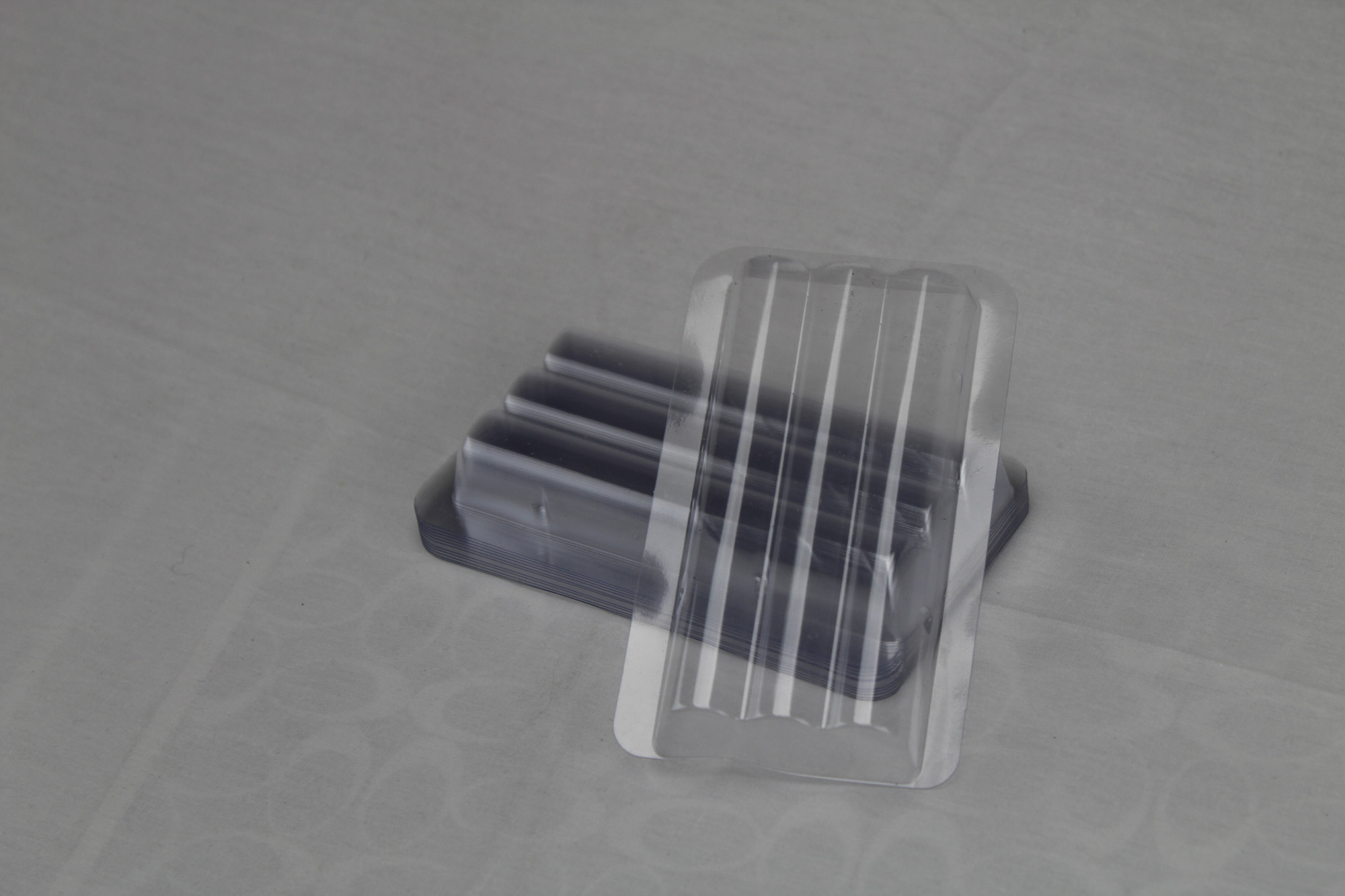

This type of package does not need a blister sealing machine. As apposed to the other two types of blister packaging, the slide-on does not cover the product only. The slide-on blister extends not only to all edges of the card, but folds around on all 4 sides. This allows a pocket to secure the blister card. This type of packaging is good for products that may need to be removed for sizing and then replaced.

All of the above cards can be purchased through us or our sister company, Clearwater Packaging

What is a Blister Package?

Get a Quote

Our professionals will be happy to discuss what you need done and how we can help ensure it is done the way you want.